- 20 Years of Expertise in Import & Export Solutions

- +86 139 1787 2118

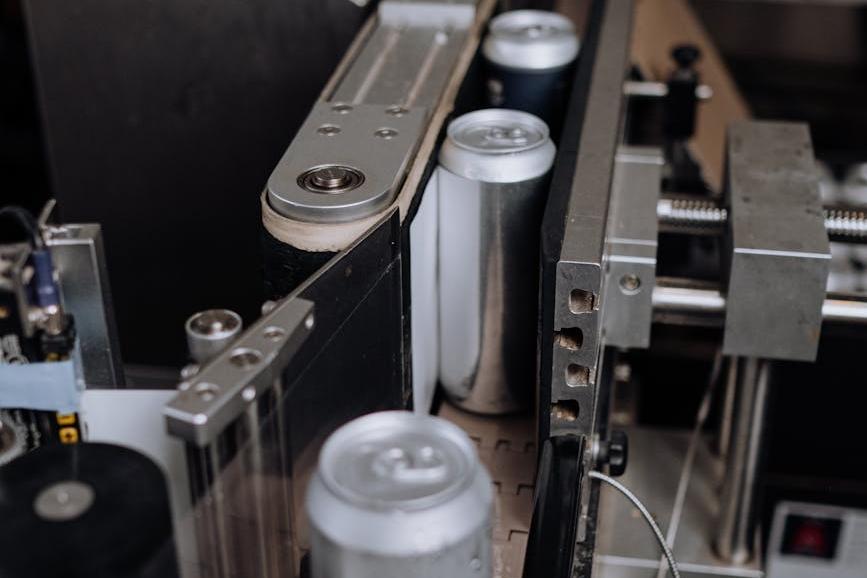

When Craft Beer Meets Imports: A Complete Guide to Customs Clearance for Beer Equipment

In 2018, I handled an import case involving a German beer production line worth $2.8 million, where the client incurred demurrage fees exceeding 5% of the cargo value due to misclassification of the filling equipment. This case made me realize that importing beer equipment is far more complex than imagined. With twenty years of...?Foreign trade?Veteran, today we'll take you through the key steps in the entire process of importing equipment.

Beer?Equipment import?The three core processes

- Qualification verification phase:

- Manufacturer's Filing in China (EU CE or US NSF Certification Required)

- Sanitary Certificate for Imported Food Machinery (Special attention to the material certification of parts in contact with alcoholic liquids)

- Customs declaration phase:

- The functional description of the equipment must be precise to specific modules (such as the mashing tun/fermentation tank/sterilizer).

- Note the difference between tariff codes 8438.60.00 and 8438.50.00 when declaring.

- Logistics delivery phase:

- It is recommended to adopt FCA trade terms to reduce transportation risks.

- The shockproof packaging must meet the ISTA 3A standard.

90% of Customers Overlook These Qualification Details

Last year, when a certain craft beer brand imported fermentation tanks from Italy, the equipment was detained at the port for 28 days due to the lack of FDA material certification for 316L stainless steel. Special reminder:

- The pressure vessel must provide ASME certification.

- Electrical components must comply with the GB 5226.1 standard.

- The filling equipment must complete the CIQ hygiene registration.

Three Practical Tips for Optimizing Customs Clearance Costs

- Modular Import Strategy:Split the entire line into individual machine declarations to leverage the tariff rate differences under the free trade agreement.

- Application for Classification Advance Ruling:Submit technical parameters to customs 6 months in advance.

- Logistics combination solution:20-foot container loading core equipment + bulk carrier transporting non-precision components

Real Case: The Comeback of Qingdao Craft Brewery

In 2022, when we acted as an agent for a Qingdao client to import Czech beer equipment, we implemented a combined solution of pre-classification + bonded warehousing + batch customs clearance, reducing their overall costs by 22%. Key operations included:

- Leverage the RCEP agreement to reduce the tariff on filling machines from 10% to 6.5%.

- Include wear parts in the after-sales spare parts for separate declaration.

- Adopt door-to-door supervised transportation to avoid secondary loading and unloading.

Special Advice for Importers

- Request the supplier to provide operation videos with both Chinese and English subtitles.

- Reserve 10% of the budget for unexpected expenses (such as container inspection fees).

- Complete the local customs registration before the equipment arrives at the factory.

Recently, a client remarked: "Importing equipment is like craft beer—every step requires time to mature." As professional agents, we recommend initiating the project at least eight months in advance. If you're planning an import, feel free to bring your equipment list for a discussion. We've prepared a comprehensive beer equipment import checklist, ready for you to take.

Recommended for You

- How Painful Is Choosing the Wrong Beer Import Agent? Three Real Cases Teach You to Avoid Pitfalls.

- Three Major Pitfall-Avoidance Guides for Imported Beer Agencies

- UK Import Food and Beverage Foreign Trade Guide: From Process to Opportunities

- The Secret Guide to French Craft Beer: When Left Bank Coffee Meets Chinese Wine Glasses

- Thailand Beer Import and Customs Clearance Guide: Have You Avoided These "Pitfalls"?

Category Case

Contact Us

Email: service@sh-zhongshen.com

Recommended for You

Contact via WeChat

? 2025. All Rights Reserved.